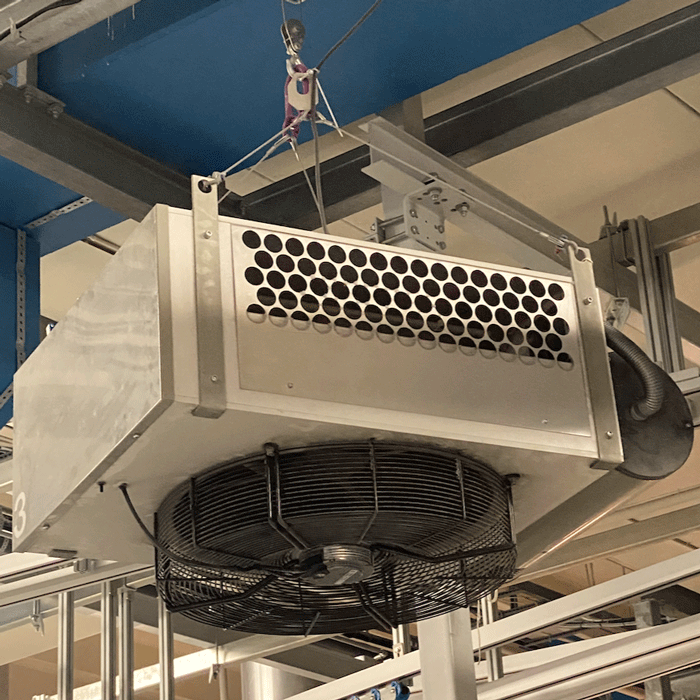

Tough times for the spread of infection in offices and classrooms

We are facing a tough virus autumn and flu winter with an increased spread of infection in offices and classrooms. Lessons from the pandemic years should be drawn, including the possibility of adding technology as one of the layers of protection in the fight against viruses and influenza.